A-A-2597A

Table I – Dimensions

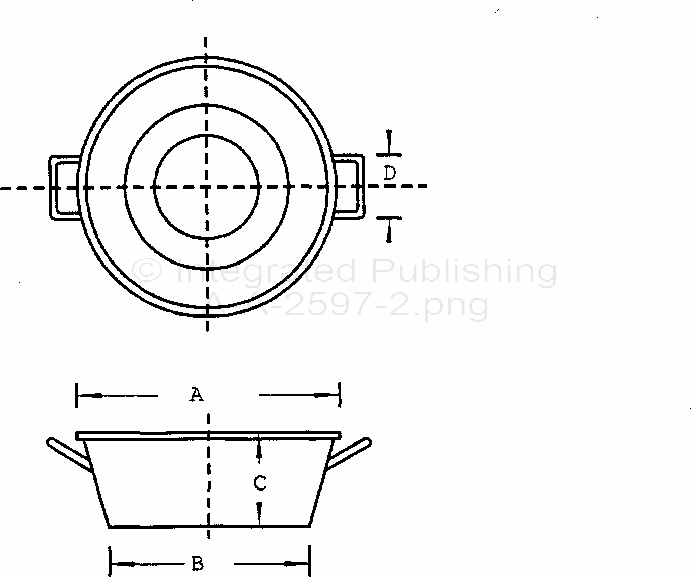

|

Size |

A |

B |

C |

D |

|

1 |

16 - 16-3/4 |

11 – 11-5/8 |

5 – 5-3/8 |

4-1/8 – 4-5/8 |

|

2 |

19 – 20 |

12-1/4 – 14 |

5-3/4 – 6-1/4 |

4-1/8 – 4-5/8 |

Note: Dimensions are listed in inches. Metric dimensions are listed in table II

at the end of the document.

3.5 Marking. The dishpans shall be marked with the manufacturer’s name,

trade name, or trademark of such known character that the source may be readily

determined.

3.6 Workmanship. The dishpans shall be clean, smooth, free from

discoloration, pits, scale, rust, cracks, punctures, scratches, grind marks,

die marks, burrs, slivers and sharp edges. The dishpans shall not be fractured,

warped or malformed, and there shall be no evidence of fractures or punctures

repaired by soldering. Welds shall be smooth, free of splatter and not

undercut. Spot welds shall be sound with no visible evidence of surface burning.

Slight visual differences (i.e., gloss) between the overall polished finish of

the pan versus the buffed area opposite spot welds shall be acceptable. The

dishpan shall be free from any other defects which may affect appearance or

serviceability.

3.7 Metric products. Products manufactured to metric dimensions will be

considered on an equal basis with those manufactured using inch-pound units,

providing they fall within tolerances specified and all other requirements of

this document are met. If a product is manufactured to metric dimensions and

those dimensions exceed the tolerances specified in the inch-pound units, a

request should be made to the contracting officer to determine if the product

is acceptable.

3.8 Standard commercial product. The dishpans shall, as a minimum, be in

accordance with the requirements of this CID and shall be the manufacturer’s

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business